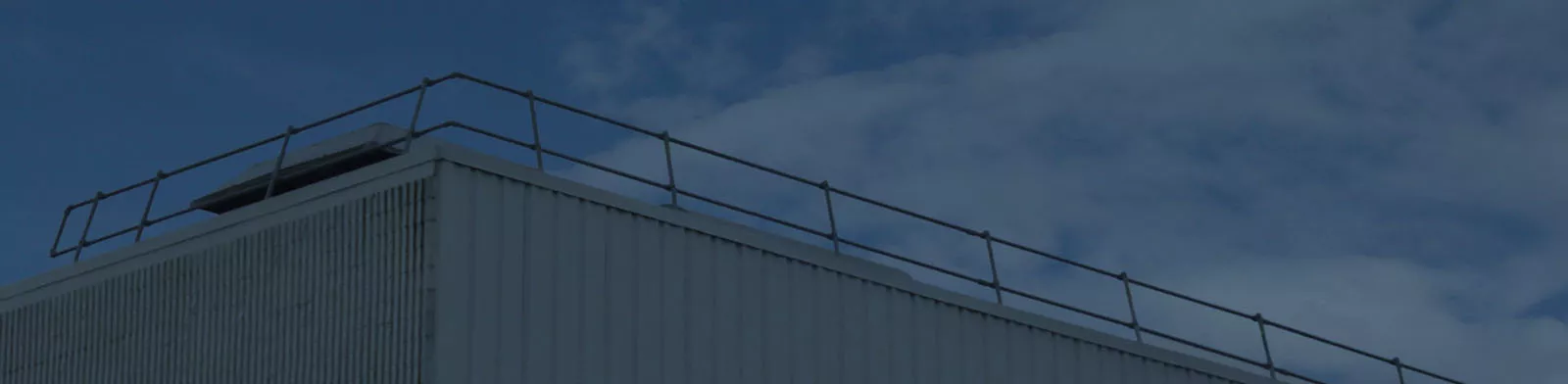

Railings grounded in safety

You are visiting the Canada Kee Safety website from United States. Would you like to go to the United States site?

The Kee Klamp system exceeds OH&S regulations and compliance, so you can rest assured your safety railing ticks all the relevant codes.

With its highly versatile and flexible modular design, our railing can be configured to the exact specifications of your site.

Kee Klamp guardrail is galvanized inside and out with a proprietary coating to guarantee corrosion resistance, even in the toughest environments.

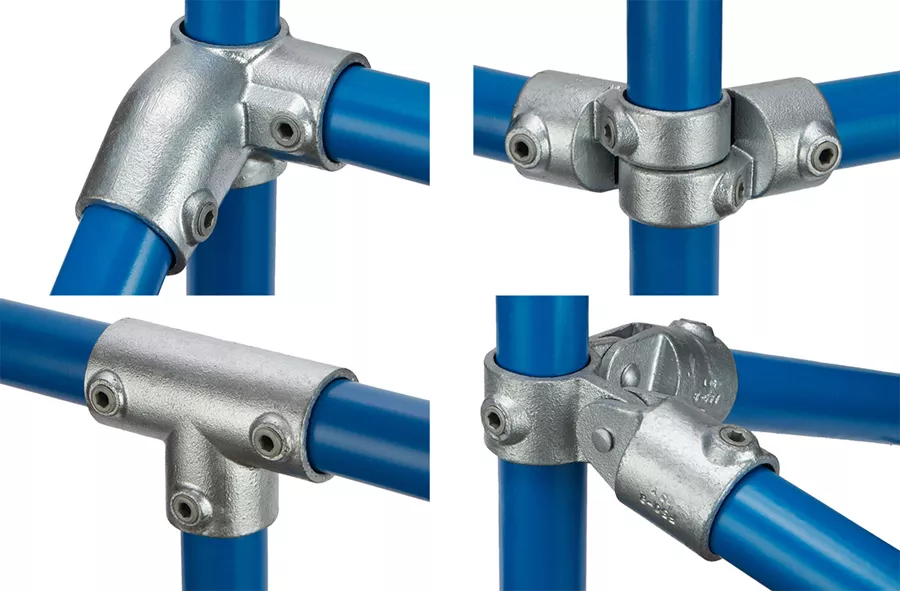

The slip-on components come together easily and are firmly locked in place with hexagon set screws. It means you don’t require any specialized labor or tools.

The engineering principle behind the Kee Klamp® fitting is the foundation of the most versatile tube connection system available. There are many variations of tubular fittings to suit a wide range of applications, providing the versatility to achieve any structural configuration.

Kee Klamp was Kee Safety's very first product invented by George H. Gascoigne and his colleagues to create a safety barrier in cow milking stalls. Since then the company has produced over 100 million fittings, many of which are still in use to day. A testament to the longevity of his design.

| Document | Format |

|---|---|

| Safety Components Guide | |

| Safety Railing Solutions | |

| Kee Klamp Sloped Fitting Brochure | |

| Kee Klamp TUV Testing | |

| Kee Klamp Components Catalog | |

| Kee Klamp - Three Part Specification | |

| Kee Klamp Installation Guide | |

| Safety Systems For Vehicle Maintenance | |

| Safety Systems for the Rail Sector |

| Document | Format |

|---|---|

| Safety Components Guide | |

| Safety Railing Solutions | |

| Kee Klamp Sloped Fitting Brochure | |

| Kee Klamp Components Catalog | |

| Safety Systems For Vehicle Maintenance | |

| Safety Systems for the Rail Sector |

| Document | Format |

|---|---|

| Kee Klamp Sloped Fitting Brochure | |

| Kee Klamp Components Catalog |

| Document | Format |

|---|---|

| Kee Klamp TUV Testing |

| Document | Format |

|---|---|

| Kee Klamp - Three Part Specification |

| Document | Format |

|---|---|

| Kee Klamp Installation Guide |

We offer full design and installation services that include a complete on-site survey. We also produce comprehensive shop drawings to help you visualize the end result. With our detailed project outline, you can be confident that your project is professionally specified, and that all safety concerns and standards are addressed to your satisfaction.

Alternatively, you can spec and install Kee Klamp yourself with our easy-to-follow instructions – it all starts with a call to our knowledgeable staff!

Please fill in your details below and we’ll be in touch shortly.